Table of Contents

- What is the Use of Y Type Valve?

- What Are Y Type Valves?

What is the Use of Y Type Valve?

Y Type Valves are indispensable components in various industrial applications, favored for their unique design and versatile functionality. Widely used in fluid control systems, pneumatic applications, and other mechanical setups, Y type valves have carved out a niche for themselves in engineering, plumbing, and contracting industries.

We will explore the definitions, functioning, advantages, and diverse applications of Y type valves while offering practical guidance on their selection, installation, and maintenance. Whether you’re an engineer, contractor, or plumber, you’ll gain valuable insights into why Y type valves should be part of your system’s design.

What Are Y Type Valves?

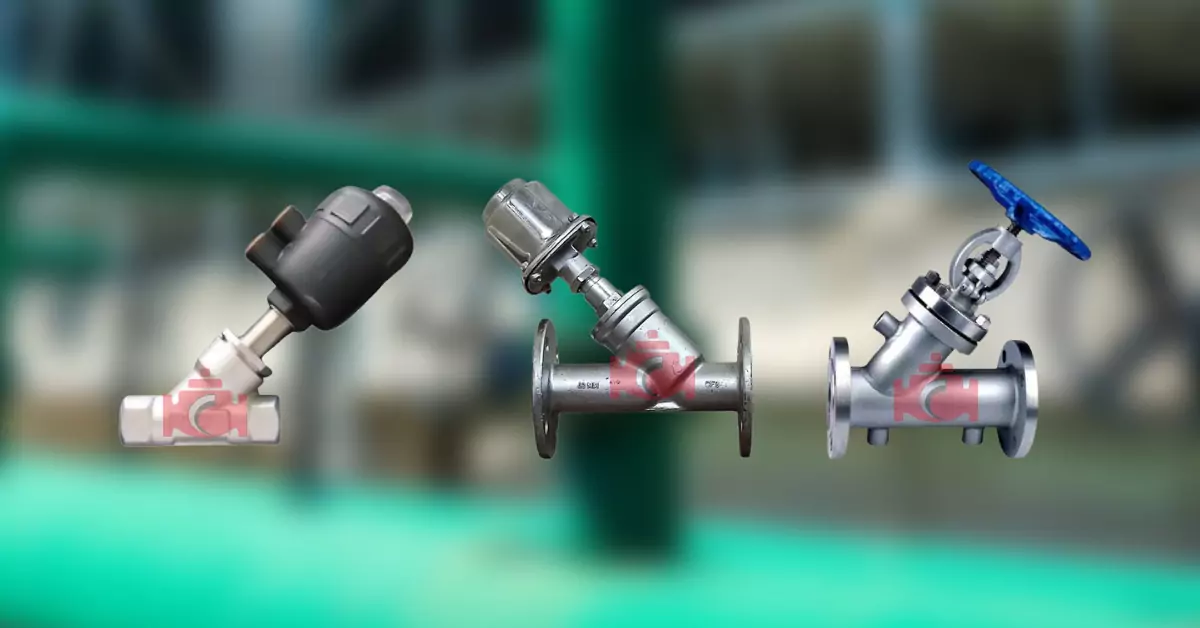

A Y Type Valve, often referred to as a Y type control valve, is a specialized valve designed to regulate, control, or shut off fluid flow within a piping system. Its name stems from the Y-shaped body configuration of the valve, which enables a more streamlined fluid flow and reduced pressure loss compared to other valve types.

Y type valves were developed to address limitations in traditional valve designs, offering improved flow efficiency and adaptability. Over the years, they have become a staple for industries that demand precise fluid or gas control in complex systems.

Core Function

At its core, the Y type valve function is to direct, restrict, or completely block the flow of fluids, gases, or steam. Whether used as a control valve pneumatic or as a pneumatic steam control valve, this versatile solution works seamlessly in high-pressure conditions and systems requiring frequent on/off operations.

Components and Materials

Y type valves consist of several key components that vary depending on their application types, including Y type pneumatic control valve or pneumatically operated valve setups.

Key Components

Valve Body: Usually made of durable materials like stainless steel, cast iron, or brass.

Actuator (for pneumatic variants): Mechanism for operating the valve, such as a pneumatic air valve actuator that facilitates on/off movement.

Ports and Seats: These ensure sealing and flow regulation for 2-way air valve or pneumatic 2 way valve configurations.

Stem and Bonnet assembly for structural strength.

Common Materials

Stainless Steel for corrosion resistance.

Brass for cost-effectiveness in small setups.

PVC for lightweight requirements.

How Y Type Valves Work

The simple yet efficient working principle of Y type valves enables them to function across varied applications. The Y-angle orientation minimizes fluid turbulence, reduces wear and tear, and ensures smoother transitions. For pneumatic options like pneumatic on off valve or pneumatic shut off valve, compressed air powers the actuator to open or close the valve.

For instance, a 3/2 pneumatic valve alternates between open and closed positions for flow regulation, while a 2-way control valve regulates flow in two directions. This streamlined operation ensures minimal energy losses in hydraulic and pneumatic systems.

Advantages and Disadvantages

Advantages

Improved Flow Efficiency: The Y shape design ensures reduced pressure drop.

Versatility: Compatible with various fluid types (water, steam, gases).

Durability: with high-grade materials like stainless steel.

Flexibility: for both manual and pneumatic valve types.

Compact Design: saves space in mechanical setups.

Disadvantages

Higher Initial Costs: compared to simpler valve designs.

Specialized Expertise: required for maintenance and troubleshooting.

Not Suitable for All Systems: needs expert assessment for specific applications.

Common Applications of Y Type Valves

- Fluid Flow Control: Ideal for industries like oil & gas, chemical processing, and water treatment facilities. For instance, pneumatic pressure control valve solutions are frequently employed to manage high-pressure liquid systems.

- Steam Regulation: Steam control valves with pneumatic actuators efficiently manage industrial boiler systems.

- Airflow Systems: Used as air control valves or pneumatic air valve controllers in HVAC and compressed air systems.

Specialized Industries

- Food Processing for hygienic water flow control.

- Power Plants employing pneumatic steam valve setups.

Selection and Installation Guidelines

Selecting the right Y type valve depends on application requirements like pressure, temperature, and flow characteristics. Here’s a step-by-step guide for optimal selection and installation:

1. Identify Your Needs

List out system specifications, such as flow rate and temperature tolerance. For instance, a pneumatic control valve may be required for automated setups, while a 2/2 valve might work better for basic flow control.

2. Compare Manufacturers and Pricing

Choose reliable Y type valve manufacturers, like Concorde Valves and Automations, for high-quality and affordable solutions. Consult Y type valve price listings to ensure the best match for your budget and application.

3. Secure Proper Installation

Follow the manufacturer’s guidelines to ensure safe and efficient operation. Whether it’s a pneumatic operated valve or a 2-way pneumatic solenoid valve, professional installation is crucial.

Maintenance and Troubleshooting Tips

Regular maintenance is vital to ensure your Y type valve delivers long-term performance. Here are some essential tips:

- Routine Inspection of components such as the actuator and seals.

- Cleaning to prevent clogging and debris buildup, especially in air-based systems like pneumatic 3/2 valve setups.

- Immediate Repairs for any signs of wear or leakage.

Common issues like inconsistent flow can often be traced back to incorrect installation or failing components. Always consult the Y type valve PDF manual for troubleshooting or reach out to your manufacturer for technical support.

Why Y Type Valves Matter for Your Systems

Y type valves, such as those offered by Concorde Valves And Automations, provide unparalleled efficiency, functionality, and adaptability for varied applications. Whether you need superior fluid management with a 2-way pneumatic valve or want to streamline steam regulation with a pneumatic steam control valve, these valves ensure optimal performance.

Take the first step toward improved control in your systems by consulting reliable Y type pneumatic control valve manufacturers. Upgrade your fluid or air control setups today with the expertise of Concorde Valves and Automation!

Y Type Valve

Y Type Valves are specially designed for regulating and controlling the flow of fluids, gases, and steam in industrial systems. Their unique Y-shaped body reduces pressure drop and enhances flow efficiency, making them ideal for applications requiring smooth and precise control.

Product Brand: Concorde Valves and Automations

Product Currency: INR

Product In-Stock: InStock

5