Manual Ball Valves Manufacturer in India | Concorde Valves & Automations

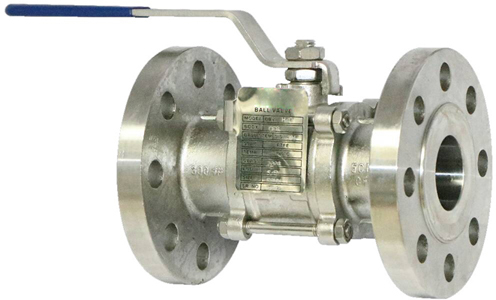

Reliable flow control starts with the right valve. Concorde Valves & Automations manufactures ISO-certified manual ball valves designed for durability, leak-proof performance, and long service life in demanding industrial environments.

As India’s trusted supplier of manual ball valves, we deliver tested, certified solutions tailored to petrochemical, water treatment, HVAC, oil & gas, and chemical industries.

Technical Specifications of Manual Ball Valves

Certified to ANSI, API, and ISO standards, our manual ball valves meet the highest levels of safety and performance.

| Material | Stainless Steel, Brass, Bronze, PVC |

| Size Range | 1/4" to 4" |

| Pressure Rating | Up to 1000 PSI |

| Temperature Range | -20°C to 200°C (-4°F to 392°F) |

| End Connection | Threaded (NPT, BSP), Flanged, Socket Weld |

| Operation | Lever Handle, Gear Operated |

| Flow Characteristic | Full Port, Reduced Port |

| Seal Material | PTFE, EPDM, Viton |

| Body Design | One-Piece, Two-Piece, Three-Piece |

| Applications | Water, Oil, Gas, Chemical Processing, HVAC |

| Compliance | ANSI, ASME, API, ISO, DIN Standards |

| Certification | ISO 9001, CE Mark, ATEX Certification |

Every valve undergoes rigorous testing to deliver consistent performance, even in high-pressure, high-temperature, or corrosive environments.

How Manual Ball Valves Work

Manual ball valves use a rotating ball with a central bore. Aligned with the pipeline, they allow full flow; turned perpendicular, they provide tight shut-off. This simple design ensures fast shut-off, precise flow control, and minimal pressure loss saving both downtime and operating costs.

Types of Manual Ball Valves

Selecting the right valve type ensures safety, uptime, and efficiency. Concorde Valves & Automations engineers multiple configurations to match your process conditions.

2-Piece Design Ball Valves

2-piece design ball valves simplify maintenance and offer robust shut-off performance. Their streamlined construction lowers lifecycle costs and suits a wide range of industrial duties.

3-Piece Design Ball Valves

3-piece design ball valves allow cleaning, inspection, and sealing component replacement without disturbing pipe connections, making them ideal where frequent sanitation or servicing is required.

Floating Ball Valves

Floating ball valves have the ball held by seats and floating slightly downstream under pressure to create a reliable seal. Best suited for low to medium pressures with excellent shut-off performance.

Full Port vs. Reduced Port Ball Valves

Full port (full bore) valves match pipeline diameter for minimal pressure loss. Reduced port valves provide compact, cost-effective control where full bore is not required.

3-Way Manual Ball Valves

3-way manual ball valves allow diversion or mixing of flow, making them versatile for complex piping systems in chemical, water, and industrial setups.

Industrial Applications for Manual Ball Valves

- Petrochemical Industry: High pressure/temperature resistance for safe handling of aggressive media while minimizing leakage risk.

- Food and Beverage Processing: Hygienic stainless steel options support sanitation, quality control, and regulatory compliance.

- Water Treatment Facilities: Corrosion-resistant construction for accurate dosing, isolation, and process reliability.

- Oil & Gas Industry: Rugged designs ensure safe handling of hydrocarbons under high pressure and temperature.

Why Quality Matters in Manual Ball Valve Selection

- Safety Considerations: Certified manual ball valves reduce leak hazards and protect personnel, equipment, and the environment.

- Reliability Requirements: Consistent, repeatable performance prevents unplanned downtime and process disruptions.

- Operational Efficiency: Long-lasting valve designs reduce maintenance costs, extend service life, and protect critical operations from costly breakdowns.

Selecting the Right Manual Ball Valve

- Proper Sizing: Match valve and line sizes to avoid excessive pressure drop and ensure required flow rates.

- Material Compatibility: Choose stainless steel for corrosive media; brass/bronze for non-corrosive; PVC for lightweight, cost-effective duties.

- Operating Condition Requirements: Verify temperature and pressure limits meet your process conditions with adequate safety margin.

Maintenance Best Practices for Manual Ball Valves

- Routine Inspections: Identify wear, corrosion, or leakage early to prevent failures and downtime.

- Cleaning Procedure: Remove debris and buildup; apply sanitary protocols where required by application.

- Lubrication Requirements: Apply proper lubrication to moving parts to ensure smooth operation, longer service life, and reduced chances of valve seizure.

Frequently Asked Questions

We manufacture floating ball valves, 2-piece and 3-piece designs, full-port and reduced-port ball valves, and 3-way manual ball valves for diversion or mixing of flow.

Options include stainless steel, brass, bronze, and PVC. Material selection for manual ball valves depends on media, temperature, pressure, and corrosion resistance requirements.

Standard sizes range from 1/4" to 4", tested up to 1000 PSI, with operating temperatures from -20°C to 200°C (-4°F to 392°F).

2-piece design ball valves are robust and cost-effective with straightforward maintenance. 3-piece design ball valves enable cleaning and seal replacement without removing pipeline connections for faster turnaround.

We offer threaded (NPT, BSP), flanged, and socket-weld end connections to integrate seamlessly with your existing piping standards for manual ball valves.

Seal options include PTFE, EPDM, and Viton. We specify seals based on chemical compatibility, temperature range, and pressure class for each manual ball valve.

Every valve is tested and inspected to international standards. Our ISO 9001 quality system and CE/ATEX compliance ensure consistent, reliable performance of manual ball valves.

Petrochemical, water & wastewater, food & beverage, oil & gas, chemical processing, and HVAC industries rely on our manual ball valves for dependable isolation and control.