Pneumatic Ball Valves Manufacturer & Supplier in India – Concorde Valves & Automations

Concorde Valves & Automations is a trusted manufacturer, supplier, and exporter of pneumatic ball valves in India. Our 2-piece and 3-piece pneumatic actuated ball valves ensure reliable flow control for industries such as oil & gas, chemical processing, pharmaceuticals, food & beverage, and water treatment. We deliver durable, cost-effective, and efficient valve solutions designed for modern industrial applications.

What Are Pneumatic Ball Valves?

Pneumatic ball valves use compressed air to operate an actuator that rotates the ball inside the valve to control fluid flow. They are ideal for automated systems and are commonly used in on/off or modulating applications. Concorde Valves & Automations offers a wide selection of pneumatic actuator ball valves engineered for performance, safety, and long service life.

Types of Pneumatic Ball Valves We Offer

We manufacture a complete range of pneumatic actuated ball valves to meet diverse industrial requirements:

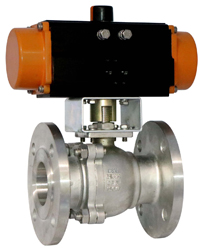

2-Piece Design Pneumatic Ball Valves

Compact and economical, these 2-piece ball valves are suited for general-purpose use. Easy to install and maintain, they provide reliable operation in industries with limited space and basic maintenance needs.

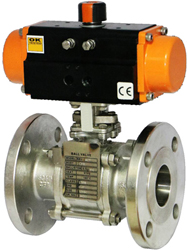

3-Piece Design Pneumatic Ball Valves

Designed for applications requiring frequent cleaning or inspection. The 3-piece pneumatic ball valves allow removal without disconnecting the pipeline, making them ideal for pharmaceuticals, food processing, and chemical plants.

Ball Valves with Pneumatic Actuators

Fully assembled ball valves with pneumatic actuators for automated flow control. Available with solenoid valves, limit switch boxes, and air filter regulators for precise operation and easy integration.

Air-Operated Ball Valves

Quick-response air-operated ball valves powered by compressed air. Perfect for emergency shutdown systems, high-cycle operations, and processes demanding fast, reliable action.

Key Features of Our Pneumatic Ball Valves

Our pneumatic actuated ball valves are engineered for performance and durability:

- Robust Design: Stainless steel, brass, and carbon steel options for tough environments.

- Wide Applications: Suitable for oil & gas, chemical processing, water treatment, pharmaceuticals, and food & beverage.

- Corrosion Resistance: Materials designed to withstand harsh conditions.

- Low Torque: Efficient operation reduces actuator stress and extends service life.

- Pressure & Temperature Ready: Handles up to 1000 PSI and temperatures from -20°C to 200°C.

- Leak-Free Operation: Advanced sealing with PTFE, PEEK, or metal-to-metal options.

Specifications of Our Pneumatic Ball Valves

| Design | 2-piece and 3-piece construction |

| Material | Stainless steel, brass, carbon steel |

| Size Range | 1/2" to 12" |

| Pressure Rating | Up to 1000 PSI |

| Temperature Range | -20°C to 200°C |

| End Connections | Screwed, socket weld, butt weld, flanged |

| Actuation Type | Pneumatic, air-operated |

| Sealing | PTFE, PEEK, metal-to-metal |

| Applications | Oil & gas, chemical processing, water treatment, pharmaceuticals, food & beverage |

| Compliance Standards | ISO, API, DIN |

Benefits of Choosing Concorde Valves & Automations

Our pneumatic ball valves are designed to provide:

- Reliable Performance: Consistent operation with minimal maintenance.

- Cost Efficiency: High quality at competitive prices for maximum value.

- Customization: Tailored pneumatic actuated valve solutions to match industry-specific requirements.

- Quick Operation: Fast response for smoother plant performance.

- Enhanced Safety: Suitable for demanding conditions with built-in reliability.

Industries We Serve

Our pneumatic actuated ball valves are widely used in:

- Oil & Gas: Flow control in pipelines and refineries.

- Chemicals: Safe handling of corrosive fluids.

- Water Treatment: Used in filtration and desalination systems.

- Pharmaceuticals: Ensuring hygienic and sterile processing.

- Food & Beverage: Meeting strict hygiene standards in production.

Why Concorde Valves & Automations Stands Out

As one of the leading pneumatic actuator manufacturers in India, we are known for quality, technology, and customer service.

- Experienced Manufacturing: Products designed to meet global standards.

- Advanced Technology: Innovative pneumatic valve designs for improved efficiency.

- Customer Focus: Timely delivery and reliable technical support.

How to Choose the Right Pneumatic Ball Valve

When selecting the right pneumatic ball valves, consider the following factors:

- Material: Ensure compatibility with the medium handled.

- Pressure & Temperature: Select a valve suitable for maximum conditions.

- Size & Design: Choose 2-piece for simple use or 3-piece for frequent maintenance.

- Sealing: PTFE, PEEK, or metal-to-metal based on application needs.