Table of Contents

Understanding the Pneumatic Control Valve Working Principle

A Pneumatic Control Valve is a key component in industrial systems that regulates the flow, pressure, or temperature of fluids by utilizing compressed air control valves its actuator. They play an essential part in automation of processes providing precise control and effective processes across various industries like the oil and gas industry and the chemical industry, water processing as well as manufacturing.

How Does a Pneumatic Control Valve Work?

The operation of the Pneumatic Control Valve is built around using compressed air for manipulating the stem of the valve or plug. This is how it works:

- Air Supply: Air is introduced into the actuator.

- Actuator movement: The actuator converts the pressure of air into mechanical motion, which can be circular or linear, in order in order to shift the stem of the valve.

- Flow Control: The motion of the stem of the valve adjusts the location of the valve plug permitting precise control of the fluid flow in the valve.

- Positioner: A positioner makes sure that your valve’s stem is at the correct position while aligning to the signal from the control.

This seamless interface ensures smooth processes and ensures accurate control of the process.

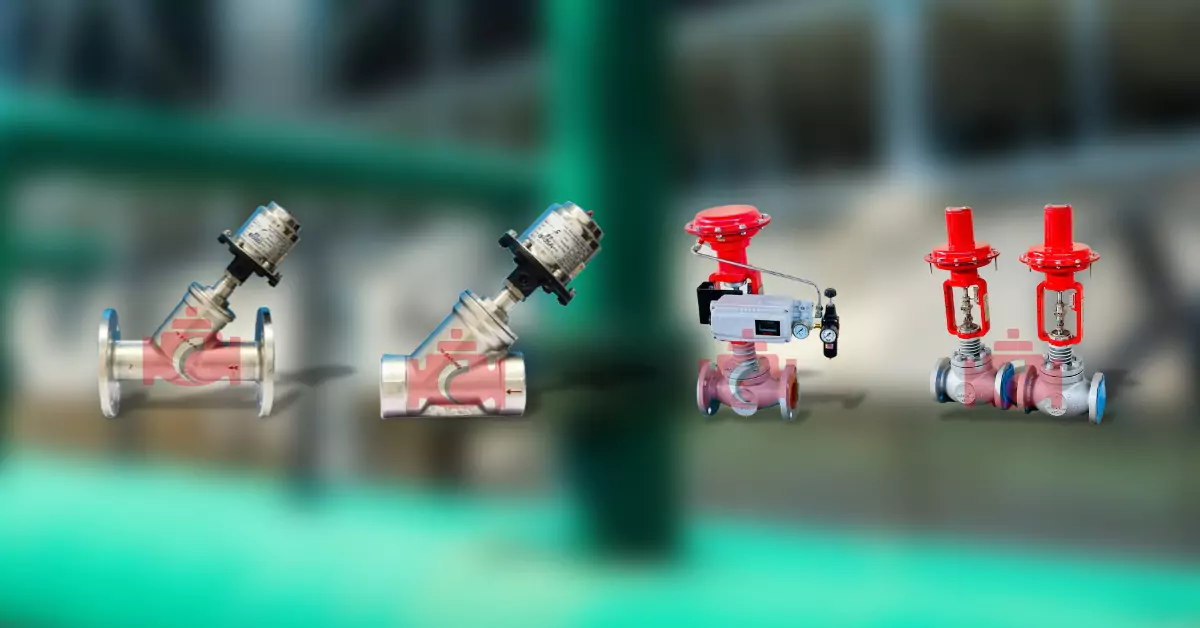

Types of Pneumatic Control Valves

1. Y-Type Pneumatic Control Valve

The valve has a distinctive design that has a Y-shaped body. It reduces tension and flow resistance. It’s ideal for use in applications needing a straight flow that is turbulent free.

2. 3-Way Pneumatic Control Valve

An adaptable option to mix or divert flow. A common use is in cooling, heating and processing applications.

3. 2-Way Pneumatic Control Valve

An easier option that has two ports. These are used to perform simple on/off and flow control applications.

4. Electro-Pneumatic Control Valve

It combines the accuracy of electrical signals along with pneumatic action for sophisticated process control. It is the ideal choice for high-performance equipment.

5. Diaphragm Pneumatic Control Valve

Utilizes a diaphragm that is flexible to control flow. It’s typically used in the sanitary and chemical industries because of its water-tight design.

Key Components of a Pneumatic Control Valve

The anatomy of the pneumatic control valve is crucial to its effective usage. These are the main components:

- Actuator: Converts pressure of air into mechanical movement, thereby driving the valve’s function.

- Valve Body: is where you can find the internal components as well as creates flow pathways.

- Stem and Plug/Disc: are moving components directly controlling the flow of liquid.

- Diaphragm or Piston: is the device that transfers power of compressed air to the stem of the valve.

- Positioner: Make sure that the valve’s location is in line to the signal for control.

- Control Signal Mechanism: Reads signals from the input to control the valve’s location.

Diagrams, Symbols, and Positioners

Pneumatic Control Valve Diagram and Symbols

diagrams, as well as P&ID symbolisms for control valve pneumatic are crucial instruments for engineers to show internal mechanisms as well as control methods. The symbol usually represents the body, actuator and flow path, giving the user with a complete picture of how the valve works within a.

Pneumatic Control Valve Positioner

A positioner is an essential device that guarantees accurate control. It relates the signal from the control to the valve’s real-time location and adjusts it in real-time to ensure precision.

Applications and Use Cases

Pneumatic control valves are extensively employed in a variety of industries due to their efficiency and reliability. The most common applications are:

- Petroleum and Gas: To regulate the flow of fluid and gas flow within pipelines.

- Water Treatment: Making sure that you get precise dosing and flow control.

- Chemical Processing: managing complex fluid mixtures that are subject to different temperatures and pressures.

- HVAC Systems: Regulating airflow and temperature within commercial buildings.

Benefits of Pneumatic Control Valves

- High Precision: Provides exact control of flow.

- Stability: Designed to stand up to extreme industrial conditions.

- Energy Efficiency: Compressed Air is a safe and effective energy source.

- Cost-Effective: Very low cost of operation and upkeep.

The product is suitable for many different types of gasses and liquids.

Why Choose Concorde Valves and Automations?

Concorde Valves and Automations is an acknowledged name for providing top-quality pneumatic solutions. We provide:

- An extensive range of items that include pneumatic pressure control valve for control Samson pneumatic valves for control and many more.

- Experience in the delivery of 3-way, 2-way, and the Y-type pneumatic control valves that are suitable for various application.

- Modern options include electronic pneumatic control valves, as well as diaphragm-pneumatic valves for control.

- Industry support with customized solutions as well as reliable services.

As a top maker of pneumatic control valve manufacturer in India We are committed to high-quality, efficiency as well as customer satisfaction. If you’re looking for simple valves or more complex control solutions, we’re there to satisfy your requirements.

To learn more about pricing for pneumatic valves specs, working fundamentals, please visit Concorde Valves and Automations today.

Pneumatic Control Valve

Explore high-quality Pneumatic Control Valve by Concorde Valves And Automations for precise industrial automation.

Product Brand: Concorde Valves and Automations

Product Currency: INR

Price Valid Until: 2025-06-30

Product In-Stock: InStock

5