Table of Contents

- Introduction to Pneumatic Rotary Actuators

- Why are Rotary Pneumatic Actuators Important?

- Key Components and Working Principles

- Types of Pneumatic Rotary Actuators

- Applications in Various Industries

- Advantages and Disadvantages

- Selection Criteria for Pneumatic Rotary Actuators

- Maintenance and Troubleshooting

- Future Trends in Pneumatic Rotary Actuators

- Unlock the Power of Pneumatic Rotary Actuators

- Why are Rotary Pneumatic Actuators Important?

Introduction to Pneumatic Rotary Actuators

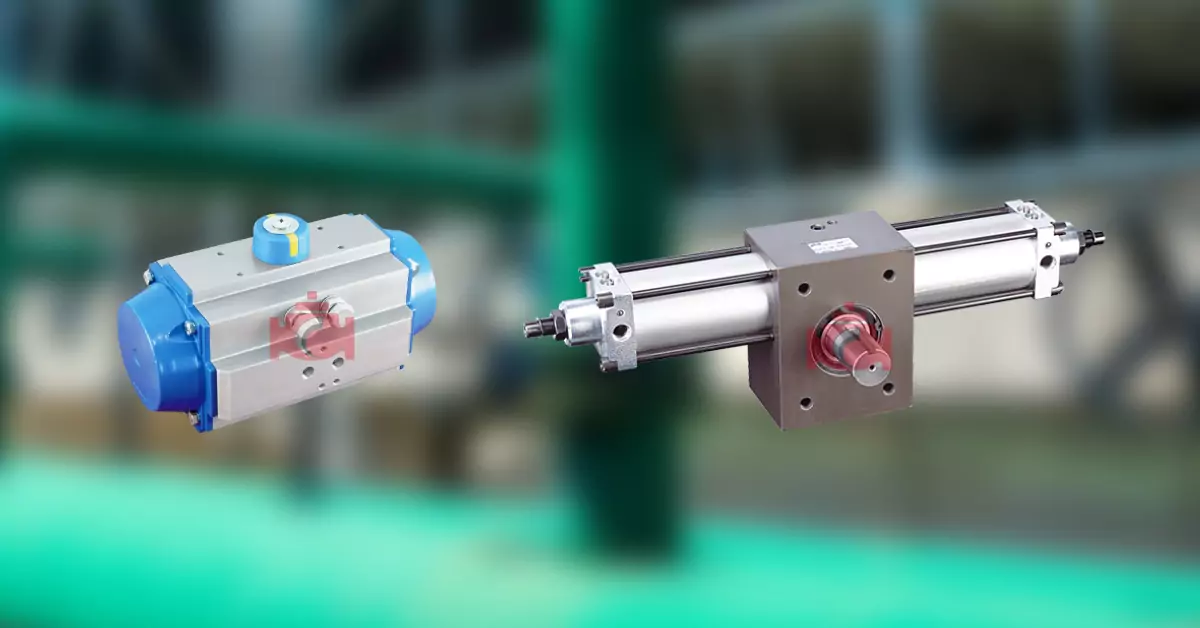

A pneumatic rotary actuator is a device that uses compressed air to produce rotational motion. Unlike linear actuators, which create straight-line motion, rotary actuators are designed to rotate an object or mechanism along a circular path. Common examples include turning a valve, positioning a robotic arm, or moving machine components as part of a larger automated system.

The operational versatility of rotary actuator pneumatic components makes them highly sought after across industries. Whether you need simple 90-degree rotation for a valve or continuous rotation for a robotic application, pneumatic rotary actuators are engineered to match your specific requirements.

Why are Rotary Pneumatic Actuators Important?

The ability to deliver precise, reliable, and high-torque rotation without the complexity of electrical systems makes pneumatic systems ideal for various challenging environments. These systems are used in sectors like manufacturing, food processing, oil and gas, and even pharmaceuticals.

Key Components and Working Principles

Understanding the components and working principles of a rotary cylinder pneumatic actuator is essential for selecting and optimizing its performance. Here’s a closer look at its main components:

Key Components:

- Cylinder – Converts compressed air into mechanical energy.

- End Caps – Seal the cylinder to contain the compressed air.

- Rotary Shaft – Translates the linear motion of the piston into rotational motion.

- Piston – Moves under the pressure of compressed air, causing rotation.

- Seals – Prevent air leakage, ensuring system efficiency.

- Bearings – Allow smooth rotational movement under load.

How it Works:

- Compressed air enters the actuator via an air control valve.

- The pressure causes the piston inside the cylinder to move.

- This linear motion is converted into rotational output through the rotary shaft.

- Depending on design, the actuator can produce rotations ranging from 90 degrees to continuous.

Modern pneumatic rotary actuators come equipped with control features such as pneumatic control valve accessories, allowing users to adjust speed, torque, and travel limits.

Types of Pneumatic Rotary Actuators

There are several types of rotary pneumatic actuators available, each suited to specific applications. Here are the most common ones:

1. Rack-and-Pinion Actuators

These actuators use a rack-and-pinion mechanism to convert linear piston motion into rotary motion. They are widely used for valve actuation in systems such as pneumatic control valve setups.

2. Vane Rotary Actuators

Vane actuators feature a simple design using a rotating vane inside the chamber. Compact and lightweight, these actuators are best for low-torque applications.

3. Helical Actuators

Helical actuators use a helical groove mechanism to produce high torque within a compact design. They are often found in pneumatic steam valves and demanding industrial applications.

4. Multi-Rotational Actuators

Unlike fixed-angle actuators (e.g., pneumatic rotary 90-degree actuators), these allow continuous rotation for applications like conveyor systems.

Choosing the right type depends on factors such as torque, speed, and environmental conditions.

Applications in Various Industries

Pneumatic rotary actuators are versatile components applicable across various industries. Here are some popular use cases:

- Manufacturing: Automating robotic arms, tightening tools, or moving assembly parts.

- Oil and Gas: Controlling pneumatic steam control valves to regulate pipeline flow.

- Food Processing and Packaging: Operating pneumatic operated valves for liquid filling systems.

- Pharma: Activating precision-controlled pneumatic on/off valves in sterile environments.

- Automotive: Used in CNC machinery where precise rotary motion is needed.

Their ability to handle demanding environments, such as high temperatures and corrosive atmospheres, makes them indispensable in industrial automation.

Advantages and Disadvantages

Advantages:

- High Torque Output relative to size.

- Simple Operation due to minimal electronic components.

- Cost-Effective, especially compared to fully electronic systems.

- Reliable in Harsh Environments, such as chemical plants or outdoor systems.

Disadvantages:

- Limited Control Precision compared to electronic actuators.

- Requires Compressed Air Infrastructure to function.

- Potential for Air Leaks, reducing efficiency over time.

When evaluating pneumatic actuator prices, consider both initial costs and operational expenses like compressed air usage.

Selection Criteria for Pneumatic Rotary Actuators

Choosing the right pneumatic rotating actuator depends on several factors. Use this checklist to guide your decision:

- Torque Requirements Match actuator torque to the rotational load for optimal efficiency.

- Angle of Rotation : Applications like valves might only need pneumatic rotary actuator 90-degree motion, while others might require 180 or continuous rotation.

- Operating Conditions : Consider temperature, pressure, and exposure to corrosive materials.

- Maintenance : Evaluate the ease of servicing components like cylinders and seals.

- Budget : Compare pneumatic actuator prices while balancing cost with performance.

Speak with the experts at Concorde Valves And Automations to find an actuator tailored to your needs!

Maintenance and Troubleshooting

To maximize lifespan and efficiency, follow these maintenance tips for rotary pneumatic actuators:

- Inspect Components regularly for air leaks or worn seals.

- Lubricate Bearings and Seals to reduce wear.

- Check Air Supply to ensure proper pressure levels.

- Calibrate actuator travel limits to maintain precision.

When troubleshooting, common issues like irregular motion or reduced torque can often be traced back to air supply or worn components.

Future Trends in Pneumatic Rotary Actuators

The future of pneumatic actuators focuses on improving efficiency and integrating with IoT systems. Expect trends such as:

- Advanced smart actuators with real-time monitoring.

- Eco-efficient designs that use less compressed air.

- Improved materials for enhanced durability.

Companies like Concorde Valves And Automations are already contributing to the innovation of air actuators, ensuring better performance and sustainable operations.

Unlock the Power of Pneumatic Rotary Actuators

From improving manufacturing efficiency to automating complex systems, pneumatic rotary actuators are indispensable tools in the modern industrial world. Select and maintain them wisely, and they’ll deliver consistent, reliable performance for years to come.

Need assistance selecting the right actuator? Contact Concorde Valves And Automations today for expert guidance and a range of solutions tailored to your needs.

Pneumatic Rotary Actuator

A Pneumatic Rotary Actuator is a mechanical device that converts compressed air energy into rotary motion. These actuators are essential in industrial automation, offering efficient and reliable movement for various applications.

Product Brand: Concorde Valves And Automations

Product Currency: INR

Product In-Stock: InStock

5