Introduction to Pneumatic 3 Piece Design Butt Weld Floating Ball Valve

The Pneumatic 3 Piece Design Butt Weld Floating Ball Valve is a highly effective solution for controlling fluid flow in industrial applications. With its innovative design and high-performance features, this valve type ensures precise, reliable, and efficient operation. The three-piece design allows for easy installation, maintenance, and repair, while the butt weld connections ensure a secure, leak-free seal. Concorde Valves and Automations provides top-quality pneumatic valves designed to optimize fluid control systems across a range of industries, including oil and gas, chemical processing, and water treatment.

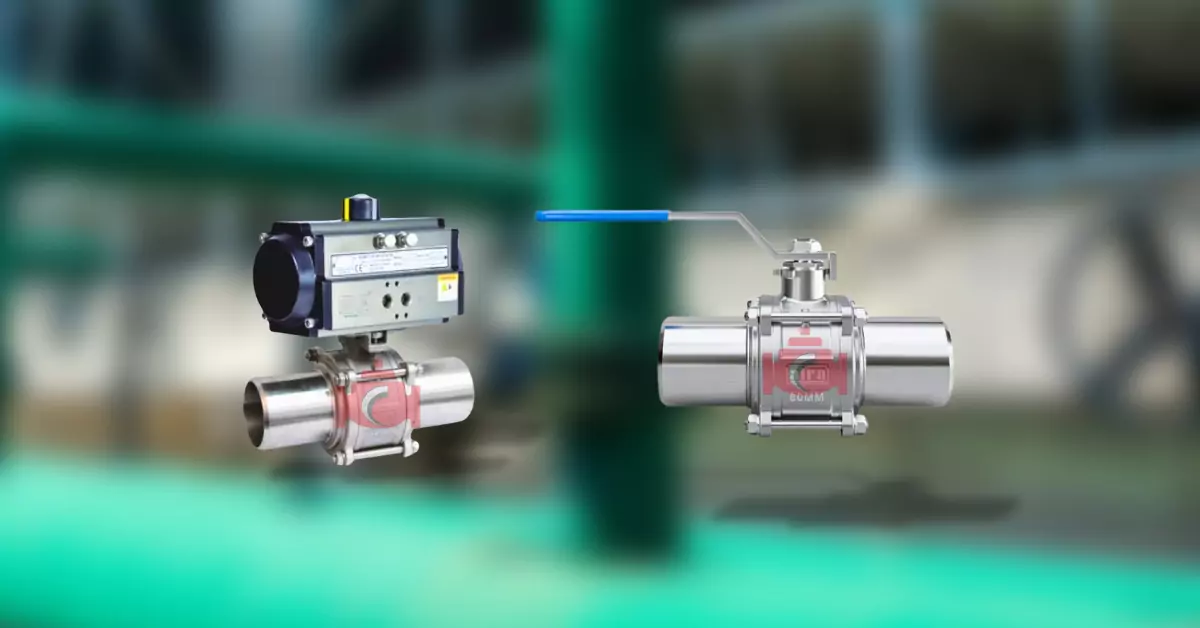

What is a Pneumatic 3 Piece Design Butt Weld Floating Ball Valve?

A Pneumatic 3 Piece Design Butt Weld Floating Ball Valve consists of three main components: the valve body, the ball, and the actuator. The ball is held in place by two seats, allowing it to float and provide a tight seal as it rotates to control the flow of fluids. The three-piece body design offers modularity, enabling easy disassembly and maintenance without removing the entire valve from the pipeline. The butt weld connection ensures that the valve is securely integrated into the pipeline, minimizing the risk of leaks or failure.

The valve operates using a pneumatic actuator, which is powered by compressed air to control the ball’s rotation. This actuation method allows for fast, efficient, and precise control over fluid flow, making it an essential component in automated industrial systems.

Key Features and Benefits of Pneumatic 3 Piece Design Butt Weld Floating Ball Valve

- Three-Piece Design: The modular three-piece construction allows for easy maintenance and repair, minimizing downtime and maximizing system efficiency. Each part of the valve can be independently serviced or replaced.

- Butt Weld Connections: These connections ensure a secure and leak-free integration of the valve into the pipeline, providing added safety and reliability.

- Floating Ball Mechanism: The floating ball design helps achieve a tight seal, even in high-pressure applications. This minimizes the risk of fluid leakage and ensures that the valve operates smoothly.

- Pneumatic Actuation: The pneumatic actuator provides fast and reliable control over the valve’s operation. It offers precise flow regulation with minimal effort, making it ideal for automated processes.

- Durability: Designed to withstand high temperatures, pressures, and corrosive environments, the Pneumatic 3 Piece Design Butt Weld Floating Ball Valve is built for long-term reliability in industrial applications.

Advantages of Pneumatic Ball Valves

Pneumatic ball valves, including the Pneumatic 3 Piece Design Butt Weld Floating Ball Valve, offer numerous advantages in industrial fluid control systems. Their primary benefits include:

- Quick Response Time: Pneumatic actuators provide faster and more accurate control of fluid flow, reducing response times in automated systems.

- Minimal Maintenance: The durable construction and modular design reduce the need for frequent maintenance, which saves time and costs.

- Cost-Effective: Pneumatic ball valves, due to their efficiency and low maintenance requirements, are a cost-effective choice for controlling fluid flow in demanding industrial environments.

Applications of Pneumatic 3 Piece Design Butt Weld Floating Ball Valve

The Pneumatic 3 Piece Design Butt Weld Floating Ball Valve is ideal for a variety of industrial applications, including:

- Oil and Gas: Used for controlling the flow of crude oil, natural gas, and other petroleum products, these valves ensure safe and efficient operation in demanding environments.

- Water Treatment: Pneumatic ball valves are widely used in water treatment plants to regulate the flow of water and other liquids in the system.

- Chemical Processing: In chemical processing, it is essential to maintain precise flow control of chemicals and other fluids. The pneumatic ball valve’s reliable performance is ideal for these applications.

- Food and Beverage: For industries dealing with food and beverages, the valve’s clean design and reliable operation make it suitable for handling various liquid and gas flows.

Product Details

- Pneumatic Ball Valve Price: The price of the Pneumatic 3 Piece Design Butt Weld Floating Ball Valve varies depending on factors like size, material, and customization. Concorde Valves and Automations offers competitive pricing to ensure that customers get the best value for their investment.

- Pneumatic Actuator Ball Valve Working Principle: The working principle of a pneumatic actuator ball valve is based on compressed air that drives the actuator to rotate the ball. This rotation opens or closes the flow path, providing precise control of fluids.

- Pneumatic Valve Manufacturers: Concorde Valves and Automations is a trusted manufacturer of pneumatic valves, offering high-quality products designed to meet the most demanding industrial requirements.

Why Choose Pneumatic Actuated Ball Valves from Concorde Valves and Automations?

At Concorde Valves and Automations, we are committed to providing high-performance, reliable pneumatic valves for all industrial needs. Our pneumatic ball valves, including the Pneumatic 3 Piece Design Butt Weld Floating Ball Valve, are engineered for precision, durability, and ease of use. Some of the key reasons to choose our products include:

- Custom Solutions: We provide customized valve solutions tailored to the specific needs of your system, ensuring optimal performance.

- Expertise and Support: Our team of experts is always available to provide guidance in selecting the right valve and offer ongoing support to ensure smooth operations.

- Commitment to Quality: All of our pneumatic valves undergo rigorous testing to meet the highest industry standards, guaranteeing reliability and safety.

The Pneumatic 3 Piece Design Butt Weld Floating Ball Valve from Concorde Valves and Automations is the ideal solution for controlling fluid flow in a variety of industrial systems. With its modular design, secure butt weld connections, and reliable pneumatic actuation, this valve ensures precise control, minimal maintenance, and long-term durability. Whether used in oil and gas, water treatment, or chemical processing, this valve is built to meet the rigorous demands of modern industrial operations.

Explore our range of pneumatic ball valves today and experience the reliability and performance that Concorde Valves and Automations brings to every industrial application.

Pneumatic 3 Piece Design Butt Weld Floating Ball Valve

The Pneumatic 3 Piece Design Butt Weld Floating Ball Valve offers superior performance and reliability for fluid control. It features a three-piece construction for easy maintenance, butt weld connections for secure integration, and a floating ball mechanism that provides a tight seal. Powered by a pneumatic actuator, this valve ensures precise flow regulation and is ideal for high-pressure applications in industries such as oil and gas, chemical processing, and water treatment. Designed for long-term durability, it is a cost-effective and low-maintenance solution for controlling fluid flow.

Product Brand: Concorde Valves and Automations

Product In-Stock: InStock

5