Table of Contents

- Different Types of Ball Valve: Designs, Applications, and Market Insights

Different Types of Ball Valve: Designs, Applications, and Market Insights

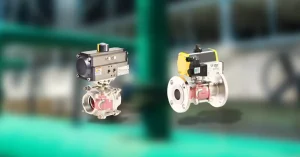

The ball valve is an important component of industrial applications. It provides highly effective fluid control in sectors like oil and gas production, pharmaceuticals and water treatment. Buyers and engineers can select the best ball valve for their needs by understanding the different types of Ball Valve that are available. Concorde Valves and Automations is a leading innovator in valve solutions. They offer a wide range of ball vales that are designed to perform and last.

What is a Ball Valve?

The ball valve uses a circular disc as a control for fluid flow. The ball can be rotated 90 degrees to either allow or prevent flow. This makes it the most simple and reliable type of valve on the market. The ball valve is a popular choice for its ability to seal tightly, shut off quickly, and have minimal leakage. This makes it ideal for applications that require precise control.

The Benefits of Selecting the Correct Ball Valve Type

It is important to select the correct type of ball vale in order to maximize efficiency, reduce maintenance costs and improve operational safety. Understanding the unique characteristics of each type is important because they are designed for different tasks and conditions.

Concorde Valves and Automations: Types of ball valves

Floating ball valve

One of the most common designs is a floating ball valve. The valve body is made up of two seats that hold a ball in place. However, the ball can also “float” inside. This allows for an airtight seal under pressure. These valves are used in gas distribution systems and HVAC applications that require tight seals.

Benefits of floating ball valves

- Design simple with less parts

- Tight shut-off even in high-pressure systems

- Easy to use and cost-effective

Trunnion Mounted Ball Valve

Trunnion mounted ball valves have been designed to handle high pressure applications. The trunnion-mounted ball valves are designed for high pressure applications. They have extra support on the bottom and top, which keeps the ball in position. The design is more stable and reduces the torque required, particularly for larger valves.

The benefits of Trunnion mounted ball valves

- Ideal for systems with high pressure, reduces wear.

- Stability enhanced with minimal torque required

- Large pipelines for oil and gas applications.

One Piece Ball Valve

The one-piece ball vales have a unified, single body which makes them less expensive and more leak resistant. They are popular for domestic and small-scale applications due to their simplicity of design. However, they were not made for high pressure systems.

How to use one-piece ball valves

- The ideal solution for water systems with low pressure

- Applications requiring minimum leakage

- General utility task budget-friendly

Two Piece Ball Valve

These valves are made up of two pieces: a body, and an end cap. This allows for easy maintenance and cleaning. They are used by industries that require regular maintenance or inspection. These valves offer an excellent balance between durability and cost, which makes them suitable for a wide range of industries.

Two-Piece ball valves: Features

- Body section removable for easy maintenance

- Ideal for cleaning systems which require frequent maintenance

- Medium-pressure application suitable

Three Piece Ball Valve

The most flexible valves for service are the three-piece ball valves (also known as split-body valves). These valves are made up of three pieces that can easily be disassembled, without affecting the pipeline. They are used by industries that require strict cleaning standards such as pharmaceuticals and food.

Benefits of three-piece ball valves

- Fast and easy service

- Ideal for clean and sterile environments

- Ideal for regular maintenance applications

Ball Valve with V-Port

This valve has a ball with a V shape. It is ideal for controlling flow. They are used to control flow in water treatment, HVAC, and chemical processing applications.

V-Port Ball Valves: Unique Features

- Precision flow control capability

- The throttling application is ideal for this product

- It is also useful for systems that require variable flow adjustment

Material Variations and Applications

The materials used to construct the different ball valves depend on their application.

- Stainless Steel : Stainless steel is commonly used in high temperature and corrosive applications.

- Brass : For low pressure systems or environments that are less corrosive.

- PVC : used in water treatment and light duty applications because of its affordability.

Ball Valves: Market Demand

Ball valves are in high demand across many industries, including oil and gas. Pharmaceuticals, energy, and water treatment. Concorde Valves & Automations are a few companies that play an important role in the industry by providing solutions tailored for specific needs. They emphasize reliability, efficiency, and safety.

Choosing the Right Ball Valve with Concorde Valves and Automations

Concorde Valves and Automations has a wide range of ball vales that are suitable for a variety of industrial applications. The company emphasizes product quality, efficiency in design and a client-centric approach to ensure that every solution aligns with the industry standard and meets customer needs. Concorde Valves offers expert advice and quality products that are tailored for each application when it comes to selecting the best valve.

Frequently Asked Questions

Which type of ball valve is best for applications requiring high pressure?

A trunnion mounted ball valve will be ideal for high pressure applications due to the extra stability it provides and its lower torque requirement.

What is the difference between a floating-ball valve and a ball valve mounted on a trunnion?

The floating ball valve is characterized by a “floating” ball, which creates a seal. A trunnion mounted ball valve, on the other hand, has an additional support that makes it ideal for high pressure settings.

Is it possible to use a ball valve with three pieces in the food industry?

Three-piece ball vales are used by many industries, including food processing, pharmaceuticals, and other areas that need easy maintenance and cleaning.

Can V-port Ball Valves be used for Throttling?

The V-shaped shape of the V-port valves makes them ideal for precise flow regulation and throttling.

What are the advantages of using an all-in-one ball valve?

The one-piece ball valves offer minimal leakage and are therefore suitable for applications requiring low pressure.

Brass ball valves are used in a wide range of applications.

Brass ball valves can be found in environments with low pressure and no corrosion, like domestic water systems.

Conclusion

The right ball valve will have a major impact on the safety and efficiency of your operation. Concorde Valves and Automations is a trusted supplier, providing a wide range of ball valves of the highest quality tailored to suit specific industry needs. This guide on ball valves and their applications will help businesses make the right decisions for their industry. Concorde Valves can provide reliable solutions for any application, whether it is a high-pressure valve, a low-maintenance one, or if you require optimum flow control.

Ball Valve

Explore the different types of Ball Valve with insights into market trends, designs, and applications by Concorde Valves and Automations.

Product Brand: Concorde Valves and Automations

Product Currency: INR

Product Price: 1200

Price Valid Until: 2025-03-31

Product In-Stock: InStock

5