Maintain Valve Equipment Longer with These 6 Essential Tips for Valve Maintenance

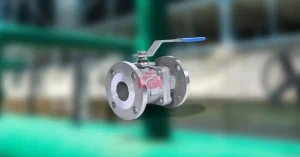

Valves are unsung heroes in industrial operations, controlling the flow of liquids, gases, and slurries across numerous applications. Yet many facilities neglect proper valve maintenance until problems arise – often leading to costly downtime, emergency repairs, or premature equipment replacement.

Proactive valve maintenance goes far beyond just preventing failures; it also involves optimizing performance, assuring safety, and safeguarding your bottom line. With proper care practices, proactive valve maintenance can extend valve lifespan by years while cutting operational costs while upholding consistent system performance.

Regular Inspection: Your First Line of Defense

Visual inspections are the cornerstone of an effective valve maintenance program. Conduct regular walk-throughs to inspect for warning signs that could indicate possible malfunction of any of your valves.

Be on the lookout for external leakage around valve stems, flanges, and body joints – even minor drips can indicate seal deterioration that worsens over time. Also check for corrosion around threaded connections and areas with high moisture accumulation; corrosion often appears where threaded connections meet moisture-laden environments.

Keep an eye on valve positioning indicators. If manual valves require excessive force to operate or automated ones have inconsistent positioning, internal components could be wearing out and need attention. Document any changes in operating characteristics as gradual degradation often precedes complete breakdown.

Be sure to inspect valve supports and mounting hardware regularly; loose bolts or damaged brackets could create stress concentrations that lead to premature valve failure.

Lubrication for Smooth Component Movement

Different valve types have different needs in terms of lubrication; Pneumatic Ball Valves and Pneumatic Butterfly Valves typically need stem lubrication regularly while gate valves might require both stem and seat lubrication at some point.

Utilize manufacturer-recommended lubricants at specified intervals to avoid over- or under-lubrication; both can attract contaminants while under-lubrication speeds wear. When operating at higher temperatures, select lubricants suitable to your operating conditions.

When lubricating, make several cycles with the valve open and closed to distribute lubricant evenly across moving surfaces and identify any binding or rough operations which might indicate internal issues. This practice also helps detect binding that might indicate internal issues.

Install grease fittings on frequently operated valves to ease regular lubrication. This small investment pays dividends in terms of reduced maintenance time and improved consistency.

Cleaning: Reducing Performance-Ruining Buildup Valves (International Association)

External cleaning prevents corrosion and facilitates inspection, while internal cleaning targets the source of many valve issues. Process fluids often leave deposits behind on valve internals that compromise sealing surfaces and restrict flow, creating flow restrictions or restricting capacity altogether.

Routine cleaning should involve flushing valves with appropriate solvents or cleaning solutions during maintenance windows, using suitable brushes or scrapers to carefully remove stubborn deposits while taking precaution not to harm sealing surfaces.

For applications prone to heavy contamination, upstream strainers should be installed to limit debris entering valves and extend their lifespan while decreasing cleaning frequency. While initial costs may increase with this decision, long-term savings and decreased cleaning frequency will become apparent quickly.

Keep valve exteriors clean and painted to prevent corrosion. Repair damaged coatings immediately as corrosion spreads quickly once protective finishes have been breached.

Proper Operation: Avoiding User-Induced Damage

Many valve failures result from incorrect user handling rather than wear and tear alone. Provide operators with instruction on appropriate operations procedures for valves while emphasizing gentle handling to minimize risks to operations and ensure optimal performance.

Over-tightening valve stems is not advised as this may damage threads and sealing surfaces, using only sufficient force to ensure proper seating. When manually operating valves are involved, establish torque limits with sufficient tools in order to limit excessive force application.

Do not use valves as supports for other equipment or piping; this creates stress concentrations which could potentially crack valve bodies or distort sealing surfaces, leading to cracks or distorted seals.

Operate valves through their full range periodically, even if normal operation doesn’t necessitate it. Doing this helps avoid sticking seats and identify emerging problems before they become critical.

Replacement: When to Say Goodbye

Even well-maintained valves will eventually wear out, making replacement indicators essential in planning maintenance and avoiding unexpected failures.

Replace valves exhibiting excessive leakage that cannot be resolved with cleaning and adjustment alone, since internal wear often exceeds replacement value.

Replacement should be considered when operation becomes challenging or inconsistent, particularly when stems, actuators, or valve bodies become worn or damaged beyond repair. Worn stems, damaged actuators, or distorted bodies rarely warrant extensive repairs on standard valves.

Plan replacements during scheduled maintenance windows whenever possible. Emergency replacements tend to cost much more and often necessitate accepting suboptimal valve selection due to limited availability.

Spare valves should always be kept for critical applications, particularly obsolete or long-lead-time models, to minimize downtime costs and keep productivity high. Carrying costs are minimal compared to extended downtime expenses.

Maximize Your Investment Through Proactive Care

Proactive valve maintenance transforms these vital system assets from potential failure points into reliable system assets. Regular inspection catches problems early, proper lubrication prevents premature wear and cleaning maintains performance for peak performance; correct operation prevents damage; timely replacement eliminates costly failures.

Valve

Learn essential valve maintenance tips to maximize equipment life, prevent costly failures, and optimize performance. Expert advice from Concorde Valves.

Product Brand: Concorde Valves and Automations

Product Currency: INR

Product In-Stock: InStock

5