Table of Contents

- Wafer Check Valve: The Complete Guide for Industrial Use

- What is a Wafer Check Valve?

- Types of Wafer Check Valves

- Wafer check valves: Benefits and Use

- Application of Wafer Check Valves

- Installing a Wafer-Check Valve

- Materials Options for Wafer-Check Valves

- Comparison of Single and Dual-Plate Wafer Check Valves

- Understanding the operation of a Wafer type Swing check Valve

- Key Differences: Wafer Check Valve vs. Traditional Check Valve

- Wafer Check Valve Maintenance Tips

- Catalog of Wafer-Type Check Valves and Customization Options

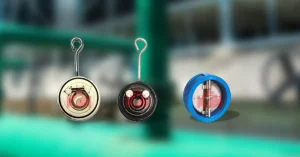

- Images of Wafer-Check Valves for Visual Reference

- FAQ

Wafer Check Valve: The Complete Guide for Industrial Use

The compactness of wafer check valves makes them an essential component in many industrial applications. They prevent backflow in pipelines and save space. Wafer check valves have a high value in industries like oil and gas processing, water treatment and chemical production because of their robustness, low maintenance and efficiency. The article will cover all the information you need about wafer-check valves including types, requirements for installation, sizes, and uses.

What is a Wafer Check Valve?

A Wafer Check Valve prevents the flow of fluids backwards through a pipe. Wafer check valves fit easily between two flanges and are lighter than conventional check valves. The streamlined design reduces the footprint of the valve, which makes it perfect for areas with restricted installation space.

The wafer check valves are operated by a disc that opens automatically with the forward flow, and shuts off when the reverse flow occurs. This prevents backflow effectively without external activation. They are popular in many industries because of their efficiency and simplicity.

Types of Wafer Check Valves

Wafer Type Check Valve

The wafer type check valve has become one of the more common types in industry. The thin design allows it to fit between the flanges of a pipeline, which reduces the need for extensive pipe modifications. Check valve wafer types is known for its simplicity and reliability. It’s ideal for applications that require quick installation.

Wafer Swing Check Valve

The wafer swing check valve uses a disc hinged to swing open and allow fluid to flow one way, then swing backwards to block reverse flow. The design of this valve is especially useful for applications that require low pressure drops and minimum resistance to fluid flow. Due to their high efficiency, wafer swinging check valves are used in industries such as HVAC, process engineering, water distribution and more.

Dual Plate Check Valve Wafer Type

The dual plate check valve wafer type has two discs or plates that open when there is forward flow, and then close once the flow reverses or stops. The durability of this type and its ability to handle high pressures make it ideal for oil, gas, and chemical applications where backflow prevention is critical.

Single Plate Wafer Check Valve

A single plate wafer check valve controls the flow with a single disk, offering an easy-to-use mechanism that requires minimal components. The simple design minimizes maintenance needs and is suitable for various low-to-medium-pressure applications, including water systems and irrigation.

Wafer Disc Check Valve

Wafer disc check valves control the flow of fluid by using a disc which moves axially inside the valve housing. A spring holds the disc in place, which allows it to respond quickly to changes in pressure. The disc is a good choice for applications that involve fluids moving quickly, because its quick response allows it to maintain a stable flow.

Wafer check valves: Benefits and Use

In industrial applications, wafer check valves have many advantages, such as their small size, affordability, and high performance. Take a look at some of their advantages:

- Space Saving Design: Wafer Check Valves are lightweight and compact, making it easy to place them between flanges. This reduces the footprint of the valve and makes them ideal for tight spaces.

- Low-Maintenance: Due to the simple design of wafer check vales, they require less maintenance than other types.

- Efficient backflow prevention: These valves protect pumps and sensitive equipment against potential damage.

- Wide range of applications: Wafer check valves are available in a variety of types, including swing, dual-plate, and single-plate.

Application of Wafer Check Valves

Oil and Gas Industry

Wafer check valves can be used in the oil and gasoline industry to stop backflow from pipelines, storage tanks, and pumps. The dual plate wafer checks are popular due to their reliability and strength in high pressure environments. They ensure safe operations in drilling and refinery applications.

Water Treatment Facilities

In water treatment plants, wafer check valves control fluid flow in filtration systems and pipes. Compact design of the wafer check valve helps to streamline water systems, and reduces contamination risk from backflow.

Chemical Processing

Wafer check valves are used in chemical processing plants to control corrosive and high temperature fluids. Single plate wafer checks are often chosen because of their durability and compatibility in chemical environments.

HVAC System

wafer type swing check valves regulate the air and water flows in HVAC systems. They prevent backflow, which could cause damage to the system, or decrease its efficiency. The space-saving features of wafer check valves make them perfect for HVAC systems where there is a limited amount of space.

Installing a Wafer-Check Valve

Wafer check valve installation can be simple, but it requires that you pay attention to the details to get the best performance. Here are general installation steps:

- Preparing the Piping System: Ensure that the pipe is clear of debris. Particles can block the valve. Verify that the flanges have been aligned properly.

- Place the Valve Correctly: Position the wafer-check valve between the flanges. Make sure that the flow direction arrow aligns with where the fluid is flowing in the pipe.

- Evenly tighten Flanges: To secure the valve, evenly tighten all bolts on the flanges. Overtightening can cause damage to the valve.

- Check for Correct Operation: After installing the valve, check to make sure it is working correctly.

Wafer Check Valve Dimensions PDF and Sizing Guide

The right size for wafer check valve installation is essential. wafer check valve dimensions PDF is often supplied by manufacturers such as Concorde Valves. It provides detailed information on sizing to assist you in choosing the right fit for your pipeline needs. The correct size is essential for proper function and to reduce the possibility of any operational problems.

Materials Options for Wafer-Check Valves

Check valves are available in a variety of materials and each is suitable for varying applications.

- Stainless Steel : Resistant against corrosion making it suitable for water and chemical applications.

- Cast iron (CI Wafer-Type Check Valve): is often used for lower pressure environments because of its cost-effectiveness and durability.

- Composites of PVC and plastic: are lightweight and corrosion resistant, and suitable for applications like irrigation.

Comparison of Single and Dual-Plate Wafer Check Valves

Both single-plate and dual-plate wafer check valves prevent backflow but they perform differently.

- Single Plate Wafer Check Valve: Has one disc, and it is designed for medium pressure. It is easier to maintain and ideal for standard applications.

- Dual Plate Wafer Check Valve: has two plates to increase stability. It can also handle greater pressures. Used in industrial settings that are demanding.

Understanding the operation of a Wafer type Swing check Valve

The wafer type swing check valve works by swinging the disc away from its seat in order to allow forward flow. The disc returns to its original position when the flow is reversed, sealing the valve. The type of valve is perfect for applications with low pressure, as it provides a simple but effective mechanism to prevent backflow.

Key Differences: Wafer Check Valve vs. Traditional Check Valve

The advantages of wafer check valves over conventional check valves are numerous.

- Compact design: Wafer Check Valves are lighter and smaller, taking up less space.

- Installation Made Easy: These can be easily installed between flanges, without requiring extensive modification.

- Lower pressure drop: Streamlined design for efficiency and minimal resistance.

Wafer Check Valve Maintenance Tips

Maintenance is essential to ensure a long-lasting product and consistent performance.

- Check the discs for wear and tear: Inspect all components, including the discs and their parts regularly.

- Clean Operation: Remove debris around valves to ensure smooth operation.

- Replacing Damaged Parts Quickly : Replace damaged parts immediately if you see any signs of damage.

Catalog of Wafer-Type Check Valves and Customization Options

Concorde Valves and Automations manufacturers offer a variety of choices for their wafer type check valve catalog. The customizations can include the material, size and pressure rating.

Images of Wafer-Check Valves for Visual Reference

The images of wafer check valves illustrate the compact designs and different configurations. Companies like Concorde Valves & Automations offer visual guides in their product catalogs or PDFs to help you understand the structure of the valve.

FAQ

What’s the difference between wafer and swing check valves?

- Wafer check valves are compact, and fit between flanges. Swing check valves have a large design, and connect directly to the pipe. For tight spaces, wafer check valves should be used.

What is the best wafer-check valve to use for my application and how do I choose it?

- You should consider factors like fluid type, required pressure, and the size of your valve. The wafer check valve catalog will help you choose the right model.

Can wafer check vales be used in high-pressure applications?

- Dual plate valves are designed to handle high pressures. For lower pressures, single plate check valves and swinging check valves may be used.

What is the recommended maintenance schedule for a wafer-check valve?

- For optimal performance, it is best to inspect the valves every 6-12months.

Which materials are used most commonly for wafer-check valves?

- Cast iron (CI), PVC, and stainless steel are all common. Cast iron (CI) is an economical option for standard applications and is suitable for harsh conditions. Stainless steel, on the other hand, is resistant to corrosion.

With their reliable performance and compact design, wafer check valves play an important role in industrial flow systems. They are popular in many industries from oil and gas to water treatment because of their versatility and easy installation. Understanding the different types of wafer check vales, their applications and how to install them will help you make an informed choice for your application. This ensures optimal performance and durability.

Wafer Check Valve

Explore the features, installation, and applications of Wafer Check Valve, including wafer swing check valves and dual plate designs for industrial use.

Product Brand: Concorde Valves and Automations

Product Currency: INR

Product Price: 1600

Price Valid Until: 2025-03-31

Product In-Stock: InStock

5