Table of Contents

- Introduction to Manual Ball Valves

Introduction to Manual Ball Valves

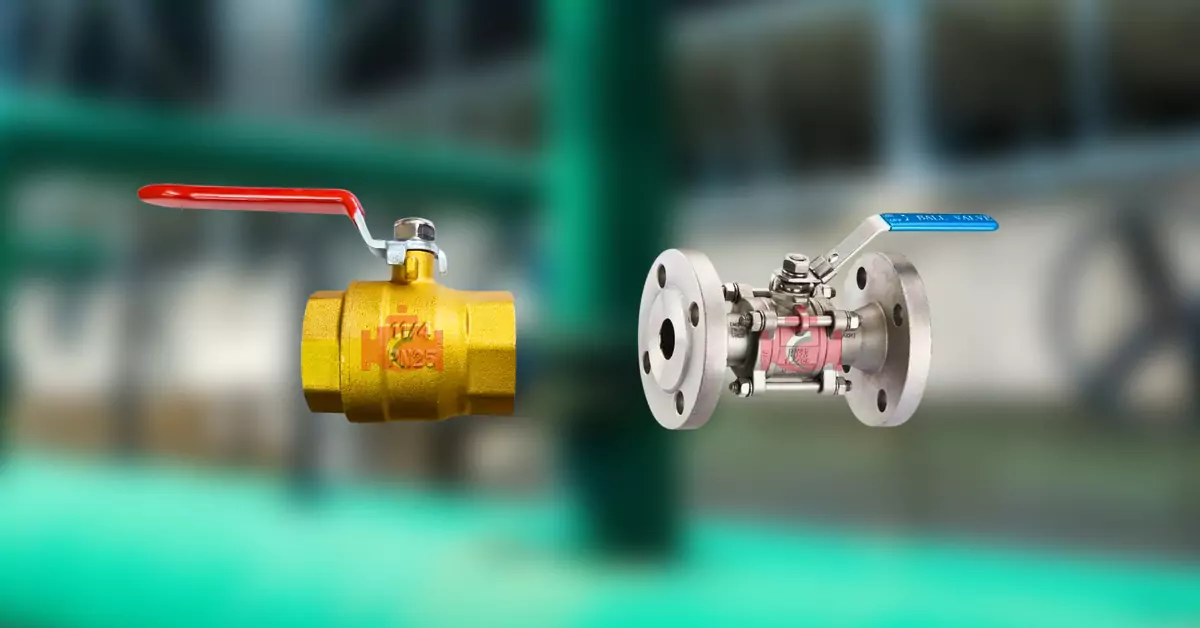

When it comes to industrial applications, precision, reliability, and durability are qualities you can’t compromise on—especially when selecting critical components like valves. One such essential component is the manual ball valves, a versatile solution widely used across industries for ensuring fluid flow control. This post dives deep into manual ball valves, meticulously created to educate engineers, plant managers, and industry professionals. Keep reading to explore manual valve types, their applications, and why Concorde Valves and Automations should be your trusted partner.

A manual ball valve is a type of valve that uses a spherical ball to control fluid flow. It’s operated using a lever or handle, making manual manipulation simple and effective. The valve allows easy on/off operation and is often used in industrial settings where precision control is necessary.

Easy to operate, cost-effective, and designed for longevity, manual ball valves are an industry favorite. Not only are they functionally efficient, but their straightforward manual valve function also makes them indispensable in pipelines, processing plants, and fluid control systems.

Types of Manual Ball Valves

Understanding manual ball valve types is crucial when selecting the right one for your application. Here are the most common types available in the Manual Ball Valves resources.

1. Two-Way Ball Valve: The two-way ball valve is the simplest form of a ball valve. It has two ports—one inlet and one outlet—and allows for straightforward flow control in one direction. These are ideal for on/off applications.

2. Three-Way Ball Valve: A three-way manual ball valve has three ports that allow it to mix or divert flows. It’s a popular choice for specific fluid-routing applications. These valves come in T-port and L-port configurations, each serving different flow patterns, making them ideal for intricate systems.

3. Full Port Ball Valve: Full port ball valves are designed to ensure the least resistance to fluid flow. They have a larger flow area and are perfect for operations where minimal pressure drop is critical.

4. Reduced Port (Standard Port) Ball Valve: Unlike full port valves, reduced port valves have smaller flow areas and are a more budget-friendly option when pressure drop is less of a concern.

5. V-Port Ball Valve: The V-shaped design of the ball in these valves makes them suitable for applications requiring precise flow regulation.

6. Manual Butterfly Valve: Not all manual valves function the same way. For instance, a manual butterfly valve uses a rotating disk rather than a ball to control fluid flow. It’s an excellent alternative when compactness and quicker actuation are needed.

Key Components and Materials

The performance of a manual ball valve depends heavily on its components and materials. Below is a breakdown of typical manual valve parts:

- Ball: The primary component that regulates flow. Usually made from stainless steel for durability.

- Body: The outer structure that houses the ball and other parts. Made from materials like brass, carbon steel, or plastic.

- Seats: These create a seal around the ball to prevent leaks. Often made of PTFE (Teflon) or other resilient polymers.

- Handle/Lever: The manual actuator of the valve, allowing easy control of the ball’s position.

- Stem: Connects the ball and handle, responsible for transmitting the actuation force.

Applications in Various Industries

Manual ball valves find applications across diverse industries. Here’s how they’re used:

- Oil and Gas: Managing the flow of crude oil and natural gas in pipelines.

- Chemical Processing: Handling aggressive chemicals with corrosion-resistant materials.

- Food and Beverage: Ensuring hygienic flow control in food-grade pipelines.

- Pharmaceuticals: Managing sensitive fluid transfer in cleanroom environments.

- Water Treatment: Controlling water flow in treatment plants and municipal supply lines.

Whether you’re controlling potable water or industrial-grade chemicals, manual valves ensure optimal performance.

Advantages and Disadvantages of Manual Ball Valves

Like any industrial component, manual ball valves have their pros and cons.

Advantages

- Ease of operation: Their simple manual function makes them user-friendly.

- Durability: Built to last with high-quality materials.

- High flow rate: Full port valves ensure minimal pressure drops.

- Versatility: Can be used across a range of applications and industries.

Disadvantages

- Manual effort: Requires human intervention for operation.

- Not ideal for automation: Limited functionality in systems requiring frequent adjustments.

Maintenance and Care Tips

To extend the lifespan of your manual ball valve, regular maintenance is essential. Here are a few tips:

- Clean the valve and components regularly to remove dirt or debris.

- Lubricate the stem periodically to ensure smooth operation.

- Inspect the seals for wear and tear, replacing damaged components immediately.

- Ensure proper storage in a dry environment to prevent corrosion.

Always refer to the manual ball valve working principle to understand its specific care instructions.

How to Select the Right Ball Valve

Selecting the right manual ball valve involves several key factors:

- Material Compatibility: Ensure the valve material is compatible with your fluid type and operating conditions.

- Flow Requirements: Choose between full port, reduced port, or V-port designs based on your flow needs.

- Temperature and Pressure Ratings: Confirm the valve can handle your system’s operational conditions.

- Size and Port Configuration: Ensure the valve matches your pipeline’s specifications.

- Certifications: Look for compliance with industry standards to ensure product quality and reliability.

Consult resources like the manual ball valve catalogue pdf for detailed specifications or reach out to trusted manual ball valve manufacturers like Concorde Valves and Automations.

Concorde Valves and Automations: Expertise You Can Trust

At Concorde Valves and Automations, we specialize in providing high-quality manual ball valves tailored to various industrial applications. With a focus on precision engineering and customer satisfaction, we consistently deliver reliability, durability, and value.

Our catalog includes a wide range of manual valve types, including manual ball valves, manual butterfly valves, and more. Plus, our team of experts is always ready to help you choose the best product for your unique requirements.

Looking for detailed specifications? Access our manual ball valve catalogue pdf today or consult our team for custom solutions.

Choose Excellence with Concorde Valves

Investing in high-quality valves is an investment in your operations’ reliability and efficiency. Whether you need precision flow control or robust components for high-pressure conditions, manual valves deliver unmatched performance when sourced from the right partner.

Visit Concorde Valves and Automations to explore our range of world-class manual ball valves. Let’s work together to elevate your systems with reliability you can count on.

Manual Ball Valves

Discover high-quality manual ball valves designed for durability and optimal performance. At Concorde Valves and Automations, we offer a wide range of manual ball valve options for various applications. Trust us as your reliable manufacturer for efficient and long-lasting solutions.

Product Brand: Concorde Valves and Automations

Product Currency: INR

Product In-Stock: InStock

5