Why Do We Use a Diaphragm Valve? Key Benefits and Applications

Control valves form the backbone of countless industrial processes, regulating flow rates and pressures across various applications. Among the many valve types available, diaphragm control valves stand out for their unique design and exceptional performance characteristics. Understanding why engineers and operators choose diaphragm valves over other options can help you make informed decisions for your specific applications.

This comprehensive guide explores the construction, advantages, applications, and limitations of diaphragm control valves, providing you with the knowledge needed to determine when these versatile components are the right choice for your system.

What is a Diaphragm Control Valve?

A diaphragm control valve is a specialized flow control device that uses a flexible diaphragm as the primary sealing and actuating element. Unlike traditional valve designs that rely on stems passing through packing glands, the diaphragm valve working principle centers around a flexible membrane that isolates the valve body from the actuating mechanism.

Basic Construction and Design

The diaphragm control valve consists of several key components:

- Valve body: Houses the flow passages and provides mounting points for the diaphragm

- Flexible diaphragm: Acts as both the closure element and the barrier between the process fluid and actuator

- Actuator: Provides the force needed to operate the diaphragm

- Bonnet or compressor: Connects the actuator to the valve body

The diaphragm control valve function relies on the movement of the flexible membrane to open and close the flow path. When the actuator applies force, the diaphragm deflects downward to restrict flow. Releasing this force allows the diaphragm to return to its original position, opening the valve.

Working Principle

The diaphragm control valve working principle is elegantly simple. The flexible diaphragm spans across the valve body, creating a complete seal between the upstream and downstream sides. When actuated, the diaphragm moves toward or away from a contoured seat, controlling the flow area and thus the flow rate through the valve.

This design eliminates the need for traditional packing arrangements, making it ideal for applications where leak-tight performance is critical.

Advantages of Diaphragm Control Valves

Understanding the benefits of diaphragm valves helps explain their widespread adoption across various industries. These advantages make them particularly suitable for specific applications where other valve types might fall short.

Superior Corrosion Resistance: The diaphragm acts as a protective barrier, preventing corrosive process fluids from contacting the valve body’s internal components. This design feature significantly extends valve life when handling aggressive chemicals or corrosive media.

By selecting appropriate diaphragm materials such as PTFE, EPDM, or other chemical-resistant elastomers, operators can achieve excellent resistance to a wide range of corrosive substances. This protection extends to the actuating mechanism, which remains completely isolated from the process fluid.

Hygienic and Sanitary Applications: Diaphragm control valves excel in hygienic applications due to their smooth, crevice-free flow paths. The absence of traditional packing arrangements eliminates potential contamination points, making these valves ideal for food, beverage, and pharmaceutical applications.

The smooth interior surfaces prevent bacterial growth and allow for effective cleaning and sterilization procedures. Many diaphragm valve designs can be completely disassembled for thorough cleaning and inspection, meeting the stringent requirements of sanitary applications.

Leak-Proof Performance: The flexible diaphragm creates an exceptionally tight seal, virtually eliminating the possibility of external leakage. This characteristic is particularly valuable when handling toxic, hazardous, or environmentally sensitive fluids.

Unlike stem-guided valves that rely on packing materials that can wear and leak over time, the diaphragm provides a permanent barrier that maintains its sealing integrity throughout its service life.

Low Maintenance Requirements: The simple design of diaphragm control valves translates to reduced maintenance needs. With fewer moving parts and no packing to adjust or replace, these valves require minimal routine maintenance.

When maintenance is required, the diaphragm can typically be replaced quickly without removing the valve from the pipeline. This feature minimizes downtime and reduces maintenance costs over the valve’s operational life.

Key Applications of Diaphragm Control Valves

The unique properties of diaphragm valves make them indispensable in several industries and applications. Understanding these applications helps illustrate why engineers choose diaphragm valves for specific requirements.

Water and Wastewater Treatment: Water treatment facilities rely heavily on diaphragm control valves for chemical dosing, flow control, and process regulation. The corrosion resistance and leak-tight performance make them ideal for handling chlorine, acids, and other treatment chemicals.

In wastewater applications, the ability to handle slurries and contaminated fluids without internal fouling makes diaphragm valves particularly valuable. The smooth flow passages minimize clogging and allow for easy cleaning when required.

Chemical Processing Industry: Chemical plants utilize diaphragm control valves extensively due to their excellent chemical compatibility and safety features. The complete isolation of the actuating mechanism from process fluids prevents contamination and protects personnel from exposure to hazardous chemicals.

The 2 way control valve configuration is commonly used in chemical processing for on-off and throttling applications. The ability to select appropriate diaphragm materials ensures compatibility with virtually any chemical process stream.

Pharmaceutical Manufacturing: Pharmaceutical applications demand the highest levels of cleanliness and contamination prevention. Diaphragm control valves meet these requirements through their sanitary design and ability to maintain sterile conditions.

The validation and documentation capabilities of modern diaphragm valves support the pharmaceutical industry’s regulatory requirements. Easy disassembly for cleaning and inspection helps maintain compliance with FDA and other regulatory standards.

Food and Beverage Production: Food and beverage manufacturers rely on diaphragm valves for their hygienic properties and ability to maintain product quality. The smooth, cleanable surfaces prevent bacterial growth and product contamination.

From dairy processing to beverage bottling, diaphragm control valves provide the reliable performance needed to maintain product safety and quality standards. The ability to handle both liquid and semi-solid products makes them versatile components in food processing applications.

Understanding Diaphragm Control Valve Types

Different diaphragm control valve types serve various application requirements. The selection depends on factors such as pressure rating, temperature requirements, and specific process conditions.

Common types include:

- Weir-type diaphragm valves: Feature a raised weir in the valve body for positive shutoff

- Straight-through diaphragm valves: Provide unrestricted flow with minimal pressure drop

- Tank bottom valves: Designed for installation at the bottom of tanks and vessels

Each type offers specific advantages depending on the application requirements and operating conditions.

Limitations of Diaphragm Control Valves

While diaphragm valves offer numerous advantages, they also have certain limitations that must be considered during selection and application.

Temperature Constraints

The flexible diaphragm material limits the operating temperature range of these valves. Most elastomeric diaphragms operate effectively within temperature ranges of -40°F to 200°F (-40°C to 93°C), though specialized materials can extend these limits.

High-temperature applications may require PTFE or other specialized diaphragm materials, which can increase costs and may have other performance trade-offs.

Pressure Limitations

Diaphragm control valves typically have lower pressure ratings compared to other valve types. The flexible nature of the diaphragm limits the maximum operating pressure, usually to several hundred PSI for most designs.

High-pressure applications may require alternative valve designs or specially constructed diaphragm valves with reinforced diaphragms.

Material Compatibility Requirements

Careful selection of diaphragm materials is crucial for successful operation. The control valve diaphragm must be compatible with the process fluid, temperature, and pressure conditions.

Incompatible diaphragm materials can lead to rapid degradation, failure, and potential safety hazards. This requirement necessitates thorough evaluation of process conditions and material properties during valve selection.

Selecting the Right Diaphragm Control Valve

Proper selection involves evaluating several key factors:

- Process fluid compatibility

- Temperature and pressure requirements

- Flow characteristics needed

- Maintenance accessibility

- Regulatory compliance requirements

Working with experienced valve manufacturers like Concorde Valves and Automations ensures proper valve selection and reliable performance in your specific application.

Maximizing Diaphragm Valve Performance

Diaphragm control valves offer compelling advantages that make them the preferred choice for many critical applications. Their leak-tight performance, corrosion resistance, and hygienic design characteristics address specific challenges that other valve types cannot match effectively.

From water treatment plants to pharmaceutical manufacturing facilities, diaphragm valves provide reliable flow control while maintaining the safety and quality standards essential to these industries. Understanding their capabilities and limitations enables engineers to make informed decisions that optimize system performance and reliability.

When properly selected and applied, diaphragm control valves deliver years of trouble-free service with minimal maintenance requirements. Their unique design continues to make them indispensable components in applications where conventional valves simply cannot meet the demanding requirements of modern industrial processes.

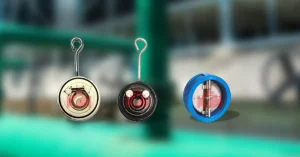

Diaphragm Valve

Diaphragm valves offer reliable flow control with a leak-proof seal, making them ideal for industries like chemical, pharmaceutical, and water treatment. Their simple design ensures durability, minimal maintenance, and compatibility with corrosive or abrasive substances, providing efficient and safe operation.

Product Brand: Concorde Valves and Automations

Product Currency: INR

Product In-Stock: InStock

5