Table of Contents

What is a Pulse Jet Valve? A Complete Guide to Industrial Cleaning

Industrial facilities face a constant battle against dust accumulation. From cement plants to power stations, particulate matter threatens equipment efficiency and air quality. Pulse jet valves have emerged as a crucial component in this fight, powering the cleaning systems that keep industrial operations running smoothly.

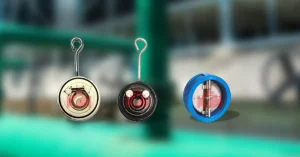

A pulse jet valve is a specialized solenoid valve designed to release short bursts of compressed air for cleaning applications. These valves serve as the heart of pulse jet cleaning systems, particularly in dust collectors and baghouse filtration systems. Understanding how these valves work—and why they’re essential—can help facility managers make informed decisions about their dust collection systems.

How Pulse Jet Valves Work

The pulse valve working principle relies on a simple yet effective mechanism that converts continuous compressed air supply into controlled bursts. When the valve receives an electrical signal, typically from a programmable timer or control system, it opens rapidly to release a high-pressure pulse of air.

The process begins with compressed air entering the valve inlet at pressures typically ranging from 5 to 8 bar. The valve remains closed under normal conditions, maintaining this pressure until activation. Upon receiving the electrical signal, the valve opens for a brief period—usually between 50 to 200 milliseconds—allowing compressed air to escape in a powerful burst.

This rapid release creates a pressure wave that travels through the connected piping system. The sudden expansion of air generates significant force, making it ideal for dislodging accumulated dust and debris from filter surfaces. The short duration of each pulse ensures efficient use of compressed air whilst providing sufficient cleaning power.

Key Components of a Pulse Jet Valve

Understanding the internal components helps explain why pulse jet valves perform so reliably in demanding industrial environments. Each component plays a vital role in the valve’s operation and longevity.

Pulse Jet Solenoid Valve: The pulse jet solenoid valve forms the electronic control heart of the system. This electromagnetic device receives electrical signals from the control system and converts them into mechanical motion. When energized, the solenoid creates a magnetic field that moves the valve’s internal components, initiating the air release sequence.

Modern solenoid valves feature weatherproof enclosures to protect against harsh industrial environments. They’re designed to handle thousands of switching cycles without degradation, ensuring consistent performance across extended operating periods.

Pulse Valve Diaphragm: The pulse valve diaphragm acts as the primary sealing element, controlling the flow of compressed air through the valve body. Made from durable elastomeric materials, the diaphragm must withstand repeated flexing whilst maintaining an airtight seal.

The diaphragm design directly influences valve performance. High-quality diaphragms use reinforced materials that resist wear, temperature extremes, and chemical exposure. The diaphragm’s flexibility determines how quickly the valve can open and close, affecting pulse duration and intensity.

Pilot Valve Assembly: The pilot valve assembly provides the control mechanism that operates the main diaphragm. This smaller valve uses a portion of the system’s compressed air to create the pressure differential needed to move the main diaphragm.

When the solenoid activates, it opens the pilot valve, allowing air pressure above the diaphragm to escape. This creates an imbalance that forces the main diaphragm to lift, opening the primary air passage. The pilot valve’s rapid response time ensures precise control over pulse timing.

Valve Body and Connections: The valve body houses all internal components and provides the pressure-rated connections for the compressed air system. Typically manufactured from aluminium or stainless steel, the body must withstand system pressures whilst providing corrosion resistance.

Standard connection sizes range from 1 inch to 4 inches, with larger valves capable of handling higher air flow rates. The body design influences air flow characteristics, affecting pulse strength and duration.

Applications of Pulse Jet Valves

Pulse jet valves find their primary application in dust collection systems, where they power the cleaning mechanisms that maintain filtration efficiency. However, their versatility extends to numerous industrial cleaning applications.

Pulse Valve for Dust Collector Systems: The most common application involves pulse valve for dust collector systems, where these valves clean filter bags or cartridges. As dust accumulates on filter surfaces, it creates resistance to air flow, reducing system efficiency. Pulse jet valves provide the cleaning bursts that dislodge this accumulated material.

In baghouse systems, pulse valves connect to a manifold that distributes cleaning air to multiple filter bags. The valve’s rapid opening creates a pressure wave that travels down the bag, causing it to inflate suddenly. This motion shakes loose the dust cake, allowing it to fall into collection hoppers.

Cartridge-style dust collectors use similar principles, with pulse valves providing the cleaning bursts that maintain cartridge efficiency. The shorter pulse duration required for cartridge cleaning demands precise valve control, highlighting the importance of quality components.

Industrial Process Applications: Beyond dust collection, pulse jet valves serve various industrial cleaning applications. They’re used in pneumatic conveying systems to clear blockages, in silo cleaning systems to prevent material buildup, and in various material handling applications where controlled air bursts provide cleaning or material movement.

Some facilities use pulse jet valves for equipment cleaning, where periodic air bursts remove accumulated material from machinery surfaces. The precise control offered by these valves makes them suitable for applications requiring consistent cleaning force.

Advantages and Disadvantages

Understanding the benefits and limitations of pulse jet valves helps facility managers make informed equipment decisions.

Advantages

Pulse jet valves offer several compelling advantages that make them the preferred choice for industrial cleaning applications. Their rapid response time ensures precise control over cleaning cycles, allowing systems to maintain optimal filtration efficiency without excessive compressed air consumption.

The compact design of pulse jet valves makes them suitable for installation in space-constrained environments. Their robust construction handles the repeated cycling required in industrial applications, often operating reliably for years with minimal maintenance.

Energy efficiency represents another significant advantage. The short pulse duration minimises compressed air consumption whilst providing effective cleaning power. This efficiency translates to lower operating costs compared to continuous air cleaning systems.

Pulse jet valves also offer excellent controllability. Electronic control systems can adjust pulse timing, duration, and intensity to match specific cleaning requirements. This flexibility allows optimisation for different dust types and operating conditions.

Disadvantages

Despite their advantages, pulse jet valves have some limitations that users should consider. The reliance on compressed air means these systems require adequate air supply capacity and pressure. Facilities with limited compressed air resources may find alternative cleaning methods more suitable.

The complexity of pulse jet systems can make troubleshooting challenging. Electronic control systems, solenoid valves, and pneumatic components all require proper functioning for optimal performance. This complexity may require specialized maintenance expertise.

Initial installation costs can be higher than simpler cleaning systems. The requirement for compressed air systems, control electronics, and properly sized valves represents a significant investment, though operating savings often justify these costs over time.

Noise generation during pulse events may be problematic in noise-sensitive environments. The rapid air release creates sound levels that require consideration in workplace safety planning.

Maintenance and Troubleshooting

Proper maintenance ensures pulse jet valves provide reliable service throughout their operational life. Understanding common maintenance requirements and troubleshooting techniques helps facility managers maintain system performance.

Routine Maintenance Tasks: Regular inspection of pulse jet valves should include checking electrical connections, examining diaphragm condition, and verifying proper pulse timing. Loose electrical connections can cause intermittent operation, whilst damaged diaphragms may result in weak pulses or complete valve failure.

Compressed air quality significantly affects valve life. Moisture, oil, and particulates in the air supply can damage internal components. Installing appropriate air treatment equipment—including filters, dryers, and oil separators—protects valve components and extends service life.

Control system calibration ensures proper pulse timing and duration. Regular verification of pulse parameters helps maintain optimal cleaning performance whilst minimising compressed air consumption.

Common Troubleshooting Issues: Weak or absent pulses often indicate diaphragm problems or insufficient air pressure. Checking system pressure and inspecting the diaphragm for tears or hardening can identify these issues. Diaphragm replacement is typically straightforward and restores normal operation.

Valves that fail to close properly may have contaminated seats or damaged diaphragms. Cleaning valve seats and replacing worn components usually resolves these problems. In some cases, compressed air contamination may require improved air treatment systems.

Electrical issues can cause erratic valve operation. Checking solenoid coil resistance, verifying proper voltage supply, and inspecting connections helps identify electrical problems. Moisture infiltration into electrical components is a common cause of premature failure.

Excessive noise during pulse events may indicate worn components or improper installation. Checking mounting hardware, inspecting internal components, and verifying proper pulse timing can help reduce noise levels.

The Future of Pulse Jet Valve Technology

Pulse jet valve technology continues evolving to meet increasingly demanding industrial requirements. Manufacturers are developing more durable materials, improved control systems, and enhanced energy efficiency features.

Smart valve technologies incorporating sensors and communication capabilities offer enhanced monitoring and diagnostic capabilities. These systems can provide real-time performance data, predict maintenance requirements, and optimise cleaning cycles automatically.

Energy efficiency improvements focus on reducing compressed air consumption whilst maintaining cleaning effectiveness. Variable pulse timing, pressure optimisation, and improved valve designs contribute to lower operating costs.

Environmental considerations drive development of more sustainable materials and manufacturing processes. Longer-lasting components reduce replacement frequency, whilst improved designs minimise energy consumption throughout the valve’s operational life.

Companies like Concorde Valves and Automations continue advancing pulse jet valve technology, offering solutions that meet evolving industrial requirements. Their expertise in valve design and manufacturing helps facilities achieve optimal dust collection performance whilst minimising operating costs.

Pulse jet valves represent a proven technology that will continue serving industrial cleaning applications for years to come. Understanding their operation, maintenance requirements, and capabilities helps facility managers make informed decisions about dust collection systems. As technology advances, these valves will become even more efficient and reliable, supporting industrial operations worldwide.

Pulse Jet Valve

Pulse jet valves are essential for efficient dust collectors, ensuring optimal airflow and debris removal. This guide explains their components, operation, and common applications. Discover maintenance tips and troubleshooting advice to improve performance and reliability in industrial environments.

Product Brand: Concorde Valves and Automations

Product Currency: INR

Product In-Stock: InStock

5